REDUCING THEIR NITROGEN

This is the story of how Align Farms reduced their ‘N’ inputs by up to 33% in one year.

Align Farms drops under 190 units N/Ha limitation one year before they need to.

Nestled beneath the Southern Alps in Mid-Canterbury, Align Farms Clareview dairy farm borders on the Ashburton River. Here, shortly after the early morning milking, we talk to Rhys Roberts, CEO of Align Farms.

With regulation waiting in the wings and then becoming a reality, change was either a choice or would be forced upon the Align team.

This is the story of how one corporate farming group, Align Farms, reduced their nitrogen inputs by up to 33% in one year, growing more grass and producing more milk.

QUICK LINKS:

Click below to be taken directly to the following sections of this story.

Rhys Roberts, CEO, Align Farms

Rhys Roberts, CEO, Align Farms

Change and improvement.

Rhys Roberts, CEO of Align Farms, knew they needed to change their nutrient programme. He and his team changed to foliar application, using a Tow and Fert, across the company’s five dairy farms. They reduced their nitrogen inputs, grew more grass, and produced more milk one year before the government regulations kick in.

Rhys Roberts has always been early to adopt new techniques of dairy farming, often trialling different things well ahead of the industry curve. In mid-2019, he was contemplating the future of dairy farming in the Canterbury basin region. His company Align Farms owns five farms and two support farms in the region. It was becoming clear that the discussion in the media, at government level and amongst the public, was increasingly focusing on the impacts of dairy farming on water quality. Rhys could see that there was a clear need to change and adapt the farm’s practices to ensure they were prepared for any future regulatory development.

Episode 1: Rhys Roberts talks about the change to foliar application of fertiliser and the Tow and Fert System across the Align Farms Group.

Align Farms settled on the Tow and Fert system becuase the machine could take granular product in it’s cheap, core form.

Running a system four farm with a conventional granular-based fertiliser programme, led by the major fertiliser companies, Rhys and his team were putting on between 250 and 280 units of nitrogen per hectare every year. Additionally, the Align group of farms would use maintenance fertilisers including P and K as well as an annual requirement of lime.

Rhys started considering how the Align Group could start reducing their use of synthetic based nitrogen products. Rhys says, “We started looking at liquid N alternatives, Tow and Fert alternatives or just making a reduction in granular fert inputs”.

“We settled on the Tow and Fert system solely because of the ability of the machine to take granular product in it’s cheap, core form, mix it with water or effluent from our own sources and apply it paddock-by-paddock.”

A chance conversation between Rhys and Ricky Taylor, a friend and local farmer, revealed a mutual interest in moving to a foliar fertiliser approach. Ricky and his wife Rebecca were wanting to move into the liquid fertiliser space by founding a contracting company. They had been looking at the different application methods available and had settled on the Tow and Fert for its versatility in dissolving N and suspending fine particle products.

Rhys made the decision to work with Ricky and Fert Solutions. This partnership would enable Align to test the Tow and Fert system without the full commitment of purchasing their own Tow and Fert.

A partnership agreement was made between Rhys (Align Farms) and Ricky (Fert Solutions) and they started on the liquid foliar fertiliser application path, both excited about how this could enable significant improvement in their environmental footprint.

LOFTY GOALS:

Reducing nitrogen inputs by up to 33% without reducing outputs.

Rhys and the Align Farms team had set themselves a goal of reducing their synthetic nitrogen inputs in year one by 200 tonne. By Christmas 2019, they were on target having reduced N inputs by 100 tonnes. By the end of May, after a long and hot summer, their total reduction in nitrogen inputs was 160 tonnes.

“The only reason we missed our target was due to the warmer weather in May. We ended up doing 3 weeks extra of N application, so we made an overall reduction of 160 tonne. Generally, our business puts on about 500 tonnes of Urea, so we have made around a 30 to 33% reduction in synthetic N inputs.”

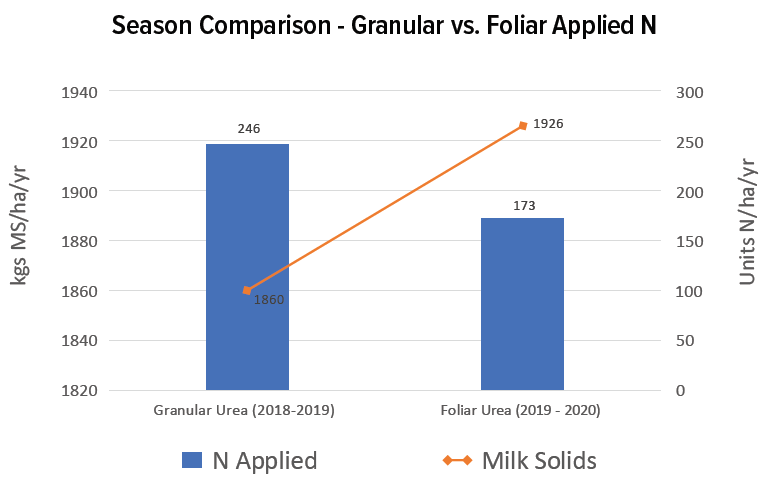

“We have managed to reduce our N inputs from an average of 246 units to 173 units, so there is a range on the farms of anywhere from 150 to 190kgs N/Ha.”

With the savings made in the business from the reduction of N, Align has been able to reinvest this money into optimising their phosphate, potassium and lime levels. They have also been able to introduce trace elements such as selenium for animal health.

Next, Rhys continues, comes the question of production “was there a drop in productivity on the farm? The answer is no. We didn’t see any fundamental shifts in our production. In fact, our calculations show we grew more grass with the Tow and Fert system.”

“Three of our farms were up on their production year-on-year, recording record production years. The test for us is to see if we can do it again. I am confident we can, whereas 12 months ago I would have laughed at you.”

“was there a drop in productivity on the farm? The answer is no.“

INPUT LIMITATIONS:

190kg N/Ha regulation is a necessary limitation.

Like any farmer, Rhys was concerned about the possibility of input regulations for his farms and the industry, but he takes a pragmatic approach when talking about the new restrictions.

“My take on the legislation and the 190 cap is that we do have to pay for our sins eventually. We need to make step changes and continue to make step changes to be more efficient.”

Rhys says, “In my view we have to get more efficient around how we use nitrogen in our systems. One area where the Tow and Fert does work well is you are taking a granular, commodified product off the shelf and mixing it with water or effluent, and using less of it during application.”

“To me it’s a no-brainer. There are savings to be made there. So not only are we already in line with the restrictions but we are also making a cash saving to our business and being efficient along financial lines as well.”

And of moving to the Tow and Fert system and meeting the restrictions soon to be in place Rhys says,

“for me it (moving to the Tow and Fert system) has moved

out of the too hard basket and into the no-brainer basket.”

REDUCING NITROGEN INPUTS:

A multi-faceted approach to reducing nitrogen use by increasing round lengths to apply less nitrogen.

As part of Align Farms nitrogen input reduction strategy, Rhys says that one additional way dairy farmers can reduce their input of nitrogen is to increase their round lengths. As most farms do about 10 rounds of fertiliser input throughout the year, increasing their round length can reduce the number of inputs a farmer puts on each year.

Rhys explains “If your round length is 21 days and you increase it to 24 days, or if you are on 25 days and move to 28 days, you can reduce your rounds to nine per year without even noticing any difference. That is a whole round of nitrogen that is now out of your system.”

“It might not seem like a big change, but it is a significant drop in N use.”

The benefit of using the Tow and Fert in a system like Rhys explains above, is that you can apply your fertiliser more rapidly after the cows have grazed the paddock and the uptake by the plant is immediate. “The challenge with a granular system is the time it can take to breakdown and become plant available. This is because we may have to wait four days to have enough area for the bulky to do the job, and then another four days to be plant available after the irrigator has been over it” says Rhys.

“One of the beauties with a fertiliser product that is in suspension or dissolved in liquid through the Tow and Fert, is that you are getting uptake in the plants on day one and growth from there going forward. You are maximising your pasture production which is critical on a dairy farm” shares Rhys.

BENEFITS BEYOND THE GROUND:

A reduction in milk urea.

Milk urea is another area that Rhys and the Align team have noticed some big changes over the course of the last 12 months. Milk urea is directly related to the pasture nitrogen levels so when more nitrogen is applied to a paddock, milk urea levels increase.

For Rhys and the team there has been a marked difference this year in milk urea.

“One area we noticed a huge change, which potentially has a link to animal health and nitrogen loss, is that our milk urea levels were substantially lower,” says Rhys.

Across the Align group of farms, the average milk urea level prior to the change to the Tow and Fert system was around 20 to 25mg/dl, the levels Dairy NZ suggest farmers can expect. Yet for the last 12 months, the Align group of farms have averaged between 3 and 5mg/dl without the expected protein drop.

Rhys explains, “we are quite confident lowering milk urea will collate to lower N loss through soils and leeching. Provided we can hold the protein level, which we believe we can, we are confident this will improve animal health and then improve the water quality leaving our farm.”

The change to the foliar application of fertiliser in a Tow and Fert at Align Farms has led to a reduction in milk urea.

LOOKING TO THE FUTURE:

Continuing to make change and improve what they do at Align.

Rhys Roberts is confident in the future of the Tow and Fert foliar fertiliser system, “we have got under 190 units across the business.” says Rhys.

The change at Align farms has been a dramatic one. With the Board determined to lead the way in all aspects of dairy farming, the early move to improve their fertiliser use and efficiency made good business sense.

“18 months ago, I thought that moving from 250 units of N down to 180 or 160 was probably going to be a big push for Align. Now, 12 months in, we have achieved those figures; we have got under 190 units across the business,” says Rhys.

With no material changes in pasture production, animal health or milk production Rhys and the Align team are confident in the future of the Tow and Fert system and business in general. “The Tow and Fert system is versatile, pragmatic and does everything that we need it to do,” says Rhys.

Rhys says Align will continue down the path they are on to ensure their results are consistent and continue to be realised year-on-year. And Rhys’ advice for other farmers considering their options for fertiliser use and meeting the new 190kgs N/ha restrictions,

“My advice to farmers is that doing nothing won’t do anything. So, let’s make change.“

Rhys Roberts, CEO, Align Farms

Book a FREE on farm demo today

CALL NOW

087 828 8542 (Ireland)

0739 351 2227 (UK)

for a no-obligation demonstration

Sam Mallard, Farm Manager, Align Farms

Down on the farm, lower inputs,

more grass and more milk.

Align Farms has always liked to pre-empt changes in the marketplace and be ahead of the curve when it comes to technology and farm management. This culture runs throughout the team and Sam Mallard, Farm Manager at Align Emilius, had a feeling that change was coming in the freshwater space in the coming years.

For Sam, there seemed to be a prime opportunity for change across the business to reduce the amount of nitrogen in the Align Farm System.

Asked whether moving to the Tow and Fert foliar system has meant a change to the Align fertiliser product programme, Sam says, “We have not changed the products we use at all. We are still using urea that comes to us as a granular prill. We were spreading that on the paddock but now it gets dissolved in the Tow and Fert machine.”

Episode 1: Sam Mallard talks aabout the change on Align Emilius, the dairy farm he manages.

Align Emilius has increased milk solids since the change to the Tow and Fert fertiliser system.

Sam Mallard say’s, “From the beginning we knew that we were growing the same, if not more grass than we had in the past. It definitely wasn’t less.”

Sam says that they could see the mass wastage of the granular urea prills during application onto the soil, “we were hoping for the best.”

Moving to the foliar application of nitrogen, Sam says they are now targeting the N being taken up directly by the plant in its leaf, meaning the product is used efficiently and its efficacy is greatly enhanced. “There is also less chance now for leeching of nitrogen. It is all used by the plant as far as we can see.” says Sam.

NITROGEN REDUCTION:

Growing the same (or more) amount of grass.

In previous seasons Align Emilius had been using, on average, around 240 units of nitrogen per hectare. Production had sat around the 1860kgs/ha milk solids. The major question in the minds of Sam and Rhys was, in changing to the foliar application of N through the Tow and Fert, would they be able to retain this level of milk solids by growing the same amount of grass.

Sam says, “at the beginning of the season, Rhys would phone me asking whether we thought there was more or less grass being grown under the Tow and Fert system. From the beginning we knew that we were growing the same, if not more grass than we had in the past. It definitely wasn’t less.”

On the performance of the farm this year “This year we did 1926kgs/ha milk solids with less nitrogen used. So that is a brilliant result for us.” says Sam. However, Sam is not one to rest on his laurels and, like Rhys, is focused on the future and improving what they are doing already,

“Now we have to go and see if we can push the boundaries of this system and continue dropping the nitrogen rate using the Tow and Fert. We need to find where the equilibrium sits.” Discovering that equilibrium is now firmly in Sam’s sights.

“Can we reduce our nitrogen inputs by 60% and still get the same results? It will be an interesting season this coming season.”

Finally, Sam offers this advice to farmers looking to drop their nitrogen inputs under the 190 limitations. “My advice to other farmers thinking of using the Tow and Fert system is that it is a very good system to help drop under the 190 units which we are now being asked to do.”

“You can drop under the 190 cap without

compromising grass growth on the farm whilst

keeping your production where it has been in the

past, if not pushing it forward into the future.”

Sam Mallard, Align Emilius Farm Manager

Book a FREE on farm demo today

CALL NOW

087 828 8542 (Ireland)

0739 351 2227 (UK)

for a no-obligation demonstration

Ricky Taylor, Tow and Fert Contractor, Fert Solutions

Partnership breeds success – Align Farms and Fert Solutions team up to test the Tow and Fert System.

Just over a year ago, Ricky Taylor and his wife Rebecca had made the decision that they wanted to get into contracting fertiliser application in the liquid fertiliser space. They could clearly see that change was coming and they wanted to be a part of that change leading the way on a contracting front.

Owning 50 hectares of semi-arable land in mid-Canterbury and managing a grazing operation, Ricky and Rebecca looked into the machinery market for the application of liquid fertiliser. They were clear with what they wanted, “we wanted a machine that could dilute or dissolve products properly and handle solid fine particle fertilisers by holding them in suspension.”

In Canterbury there is now liquid nitrogen available however, this is dissolved offsite and then the liquid N is transported to individual farms where it is applied through a traditional boom sprayer. This method of application is expensive. Ricky says,

Episode 1: Ricky Taylor talks about purchasing a Tow and Fert Multi 4000 and making the change to a foliar application fertiliser system.

Ricky with his Tow and Fert Multi 4000 spraying fertiliser on his farm in mid-Canterbury.

Episode 2: The Fert Solutions and Align Farms partnership has brought benefits to both members. Ricky reviews the Tow and Fert Multi 4000.

“We eventually found the Tow and Fert system and

immediately could see the benefits. Farmers can cart in

their dry product, dilute it down and away we go.”

This meant that clients of Fert Solutions were only paying the same rates for their dry product and with the reduction in fertiliser required, would end up making significant savings in their own businesses on a financial front as well as in reducing their fertiliser use.

VERSATILITY, EASE OF USE, GREATER PRODUCTION:

Liquid application of fertiliser delivers the goods.

During his search for a machine that could provide Fert Solutions with their required outcomes, Ricky had been talking with Rhys from Align Farms. They had talked about the potential for a partnership and so with a contract signed, Ricky was able to move forward with the Tow and Fert and begin work with Align Farms as a foundation client.

Align Farms came from a solely granular system, but the decision was made to go quite hard in the first year with the liquid foliar application. Ricky says “Align were applying phosphates, urea etc. in solid form. Then we came in and put everything on through the season using a Tow and Fert. They grew more grass and had more production. They were pretty happy at the end of the day.”

CONTRACTING FERT SOLUTIONS:

Growth and change, two constants for Ricky and Rebecca.

The uptake for Fert Solutions has been steady. The biggest hurdle has been in changing people’s mindsets on how to apply fertiliser and still get the results farmers expect. With granular fertiliser being the only option for decades, farmers have had it drummed into them that that was the only way to apply fertiliser. Ricky says, “changing people’s mindsets has been the hardest thing.”

On the positive side, Ricky says he is starting to see a change, “Farmers are getting there now as younger farmers come through and they know they have to change. The new freshwater policy has meant that many farmers are keen to give the Tow and Fert foliar system a crack.”

“The Tow and Fert fits really well with the new policy because you can use less and apply it in little amounts more often. I can see the Tow and Fert being massively used in New Zealand with the change coming.”

Ricky Taylor, Fert Solutions, Tow and Fert Multi 4000 Contractor

On their own farm Ricky and Rebecca have changed their own farming practices. “It’s a good thing. It has been a good learning curve and playing around with different fertilisers has shown us what we can do. We have been able to apply this with our clients as well. It’s been a fun 12 months.”

Ricky says, “You can pretty much put anything through it you want, as long as it will dilute, or you can keep it spinning around.” And on the machine itself, the Tow and Fert Multi 4000, Ricky has this to say, “the Tow and Fert is very well made. As a contractor the maintenance programme is good, as we go through a fair few parts with the nature of fertiliser. Getting parts out of Tow and Fert is very easy. The service from Tow and Fert has been exceptional.”

For people wanting to get into foliar application and the Tow and Fert system Ricky says, “surround yourself with good people, fertiliser reps, and agronomists who understand it and want to change. I think you will be pleased once you buy one and get into it. You’ll grow a lot of feed.”

“Or even better, find a contractor who can do it for you.” Ricky says, with a smile.

Contact Ricky @ Fert Solutions on 027 648 6856.

Book a FREE on farm demo today

CALL NOW

087 828 8542 (Ireland)

0739 351 2227 (UK)

for a no-obligation demonstration

Keep up to date with our newsletter

The Tow and Fert Times.

The Tow and Fert Times is a publication full of information for dairy farmers. Designed to help you with your nutrient management and fertiliser decisions, it is packed full of helpful information, case studies and helpful tips and tricks for the farm.

Volume 9 Available now!